Tips for Hair Cutting Shears and Tools

Click a link below

-

Loose tension will cause immediate and destructive wearing of shears

-

Reduce the premature loss of your sharp cutting edge

-

Increased possibility of causing a serious nick or abrasion on the blades

-

Increased chance of dropping your shears when they are loose

-

It only takes a few seconds to check and adjust the tension on your shears

-

The drive by street grinder makes his living off of people who won't pay attention to this simple procedure

Adjust tension with the blades closed

-

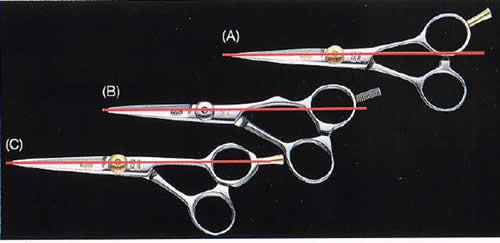

Hold your shears by the thumb ring, with the point at 12:00 o'clock (see figure A)

-

Open the other blade by the finger ring until the point is at 9:00 o'clock (see figure B). Let finger ring blade fall free.

-

If your shears have a hand adjustable tension system that clicks when it is turned; or a rubber base under the knob; the blade should stay at the 9:00 o'clock position when released. (see figure B)

-

If your shears have a regular tension screw, the blade must stop at 11:00 o'clock when released (see figure C)

-

If your shears have any other type of hand adjustable tension system, the finger ring blade should stop at the 10:00 o'clock position (see figure D)

-

Adjustments should be made as close to these examples as possible

-

On regular screw systems use tool provided with shears or use a screw driver that fits snug. Be careful not to damage screw or shears. With blades closed, place against a solid wood surface while tightening.

-

If you cannot adjust your shears tension, clean them and try again

Offset Shears ~ Why are so many haircutters using them?

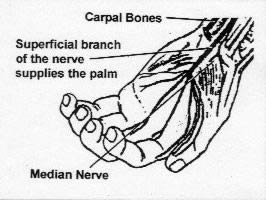

Tens of thousands of hairdressers suffer unnecessarily from the effects of cutting hair. That's because the repetitive wrist motion required to open and close shears causes the Median Nerve in your hand to rub against a narrow space in the underside of your wrist called the Carpal Tunnel.

Repeating this movement thousands of times, day after day, can damage the nerve and cause tingling, numbness or pain to the areas it supplies: the thumb, index finger, middle finger and ring finger. The resulting condition is called Carpal Tunnel Syndrome.

Shears designed with offset handles help prevent Carpal Tunnel Syndrome and increase comfort by relaxing your elbow downward, leveling your wrist in a more neutral cutting position and limits flexing of the wrist; thereby reducing wrist motion and the pressure on the Median Nerve.

Handles

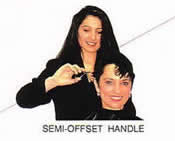

Showing angle of offset in handle design

(A) Straight (B) Semi-offset (C) Offset

Crane Handle

The crane handle is also offset but it has one significant difference. If you hold the blades of crane shear horizontally, the handle will angle downward instead of being centered on the blades. This dramatically improves the ergonomics because it relieves and prevents stress on the thumb, arm and shoulder by allowing the hairdresser to cut with their elbow in a lower position. The same angle of the handle also moves the stylists hand away from the body when cutting on the skin allowing for a freer more open cut. For most stylists, a crane handle shear is recommended to relieve stress and minimize risk of Repetitive Strain Injury, or Carpel Tunnel Syndrome. Some Crane handles also have an anatomical thumb as well.

Typical Cutting Positions

Using Professional Hair Styling Shears

Handle Grips

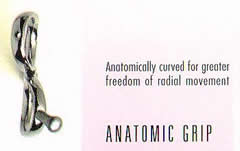

Anatomic Grip

Anatomically curved for greated freedom of radial movement

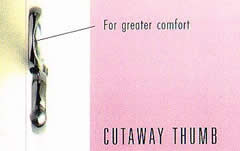

Cutaway Thumb

For greater comfort

Standard Grip

Removable / reversible finger rest can be attached to either side for left or right handed sylist compatibility

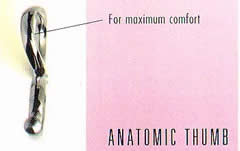

Anatomic Thumb

For maximum comfort

Blade Designs

There are only two types of shear blades. Choose the performance you need.

Beveled Edge

The oldest blade design. Can cut well, but requires more force than the convex blade.

Convex or Hamaguri Edge

State of the art, smoother cutting blade. A must for slide cutting. These are harder to make and therefore more expensive, but worth it.